Additional services

STERIGENE offers specific and complementary solutions adapted to each customer problem.

- Creation and optimization of cycles

- Steam network expertise

- Trap expertise

- Moving machine

- Chemical cleaning of autoclave chamber

- Steam quality control

- THEMA4 control system

- Derouging treatment

- Aeraulic solutions

All of these operations are carried out by our specialized technical team. The list above is not exhaustive and we can also offer you additional solutions according to your needs after study by our project and technical departments.

Our partner STAURATEC also offers specific additional services.

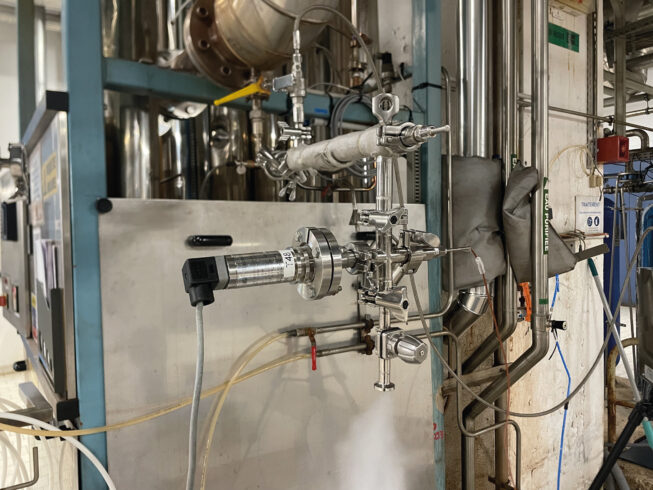

Steam quality control in accordance with standard EN285

The EN285 standard is dedicated to process equipment using steam for sterilisation purposes. It requires manual tests to be carried out to check the quality of your steam : QP/VAP control.

This control, which STERIGENE recommends carrying out annually, enables you to meet the criteria of the standard, but also to follow up non-conformities in Performance Qualification (PQ) or to obtain detailed reports during audits.

STERIGENE can provide you with its expertise, qualified technicians and the necessary equipment to carry out the following tests :

- Title test

- Non-condensable gases (NCG)

- Overheating

- Pressure/temperature correlation

- Condensate analysis

We also offer the purchase or rental of a steam quality control device: STEAM QM 3. The ARMSTRONG STEAM QM-3 is the only equipment patented for its ability to control saturated steam to international standards. It is an automated, reliable and portable device (simple ‘Plug and Play’ installation) enabling continuous tests to be carried out reliably and reproducibly (accuracy +/- 1%).

THEMA4 control system

STERIGENE offers the installation or updating of THEMA 4 control software on your process equipment. THEMA 4 is a fast and efficient process controller that has many useful features for your production lines.

- Functional architecture

- Simple use

- Optimized cycle visualization

- Alarms for problem detection

- Cycle memorization

- Creating multiple passwords

- Continuous software update (option)

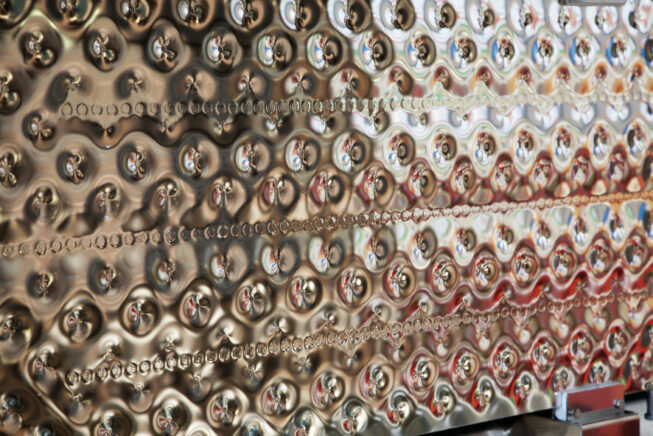

Derouging treatment

Reddening is characterized by a coloring of the stainless steel surfaces of parts and elements of process equipment in clean steam and ultra-pure water distribution networks.

This formation of more or less stubborn iron oxide layer must be eliminated to avoid oxidation of the stainless steel and in the most extreme cases contamination of pure fluids and therefore of batches in production.

STERIGENE offers curative or preventive derouging interventions in order to clean the elements of process equipment in pure fluid networks.